How It Works:

Products, technologies & services from a single source.

From concept phase to product validation:

We discover insights about real product usage and support to achieve data driven product development: see your product usage through the eyes of your customers.

ESTINO Engineering Toolchain:

From hardware and software solutions for logging the real product usage, to technologies for visualization & analysis of the product application spectrum, to computational engineering: we provide customized solutions and individual services.

Technical feedback from real product usage

The Estino.edge product family enables mobile & maintenance free data logging of measurements, telematics, metadata, sensor signals and ECU information during real product use.

We support the individual configuration of the plug & play solution and the equipment of serial products, test vehicles, vehicle fleets, industrial plants, etc..

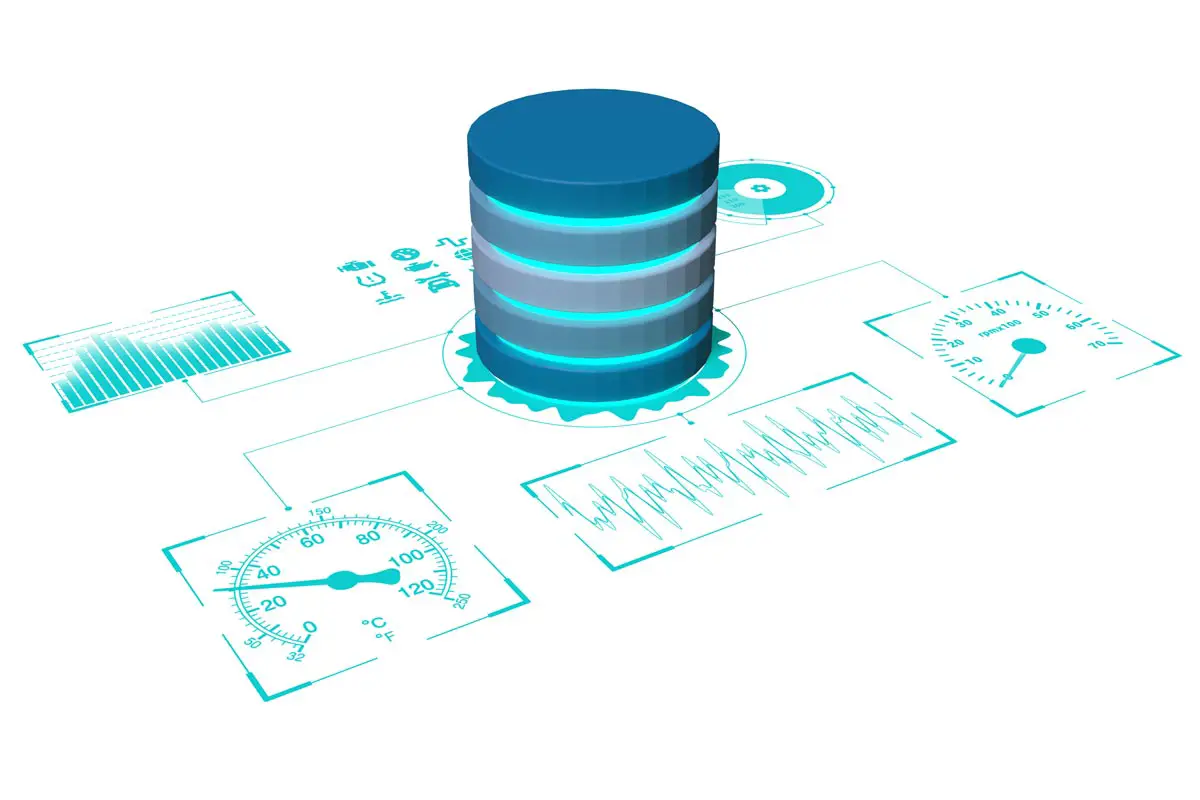

An accurate, maintained and common database for in-house use.

Individually configurable database solution for automated integration of measurements, telematics and metadata according to customized specifications and requirements.

We provide support for the individual configuration and ensure an up-to-date, maintenance free and accurate data source for development tasks.

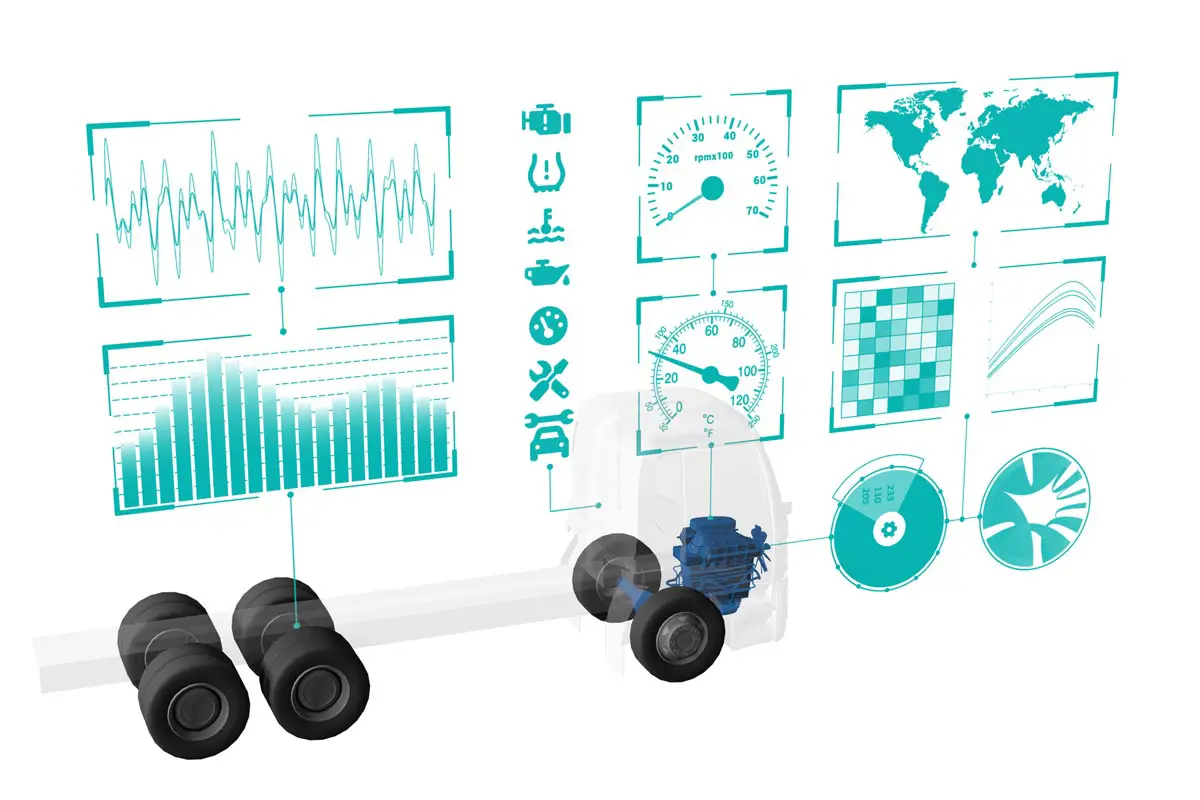

Insights about real product use:

From product development to aftersales service, have your product usage always in focus.

A cross domain and transparent platform for data visualization, analysis and internal communication that not only meets engineering requirements, but also allows non-specialized insights into the collected data. The key features are the clear representation, meaningful correlation and automated availability of many different data types and extensive measurement campaigns.

We support the individual configuration to customer-specific interfaces & requirements.

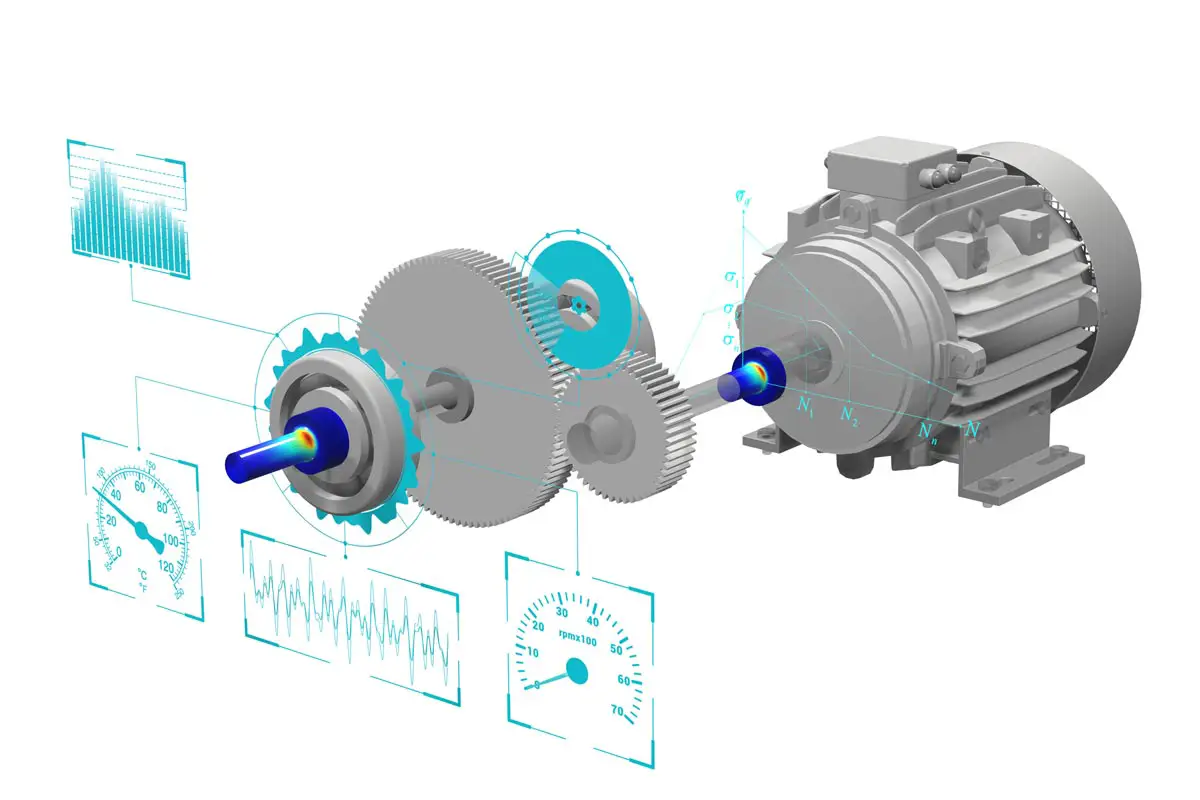

Fatigue & Durability, Condition Monitoring & Predictive Maintenance.

The knowledge of real product usage or component loads allows precise insights into product life, fatigue and failure probability. The essential goal is to use the collected data for durability and engineering analyses.

We develop customer specific methods and software solutions for the analysis of product utilization, remaining life prediction, fatigue & durability. We also support the setup of condition monitoring and predictive maintenance systems.

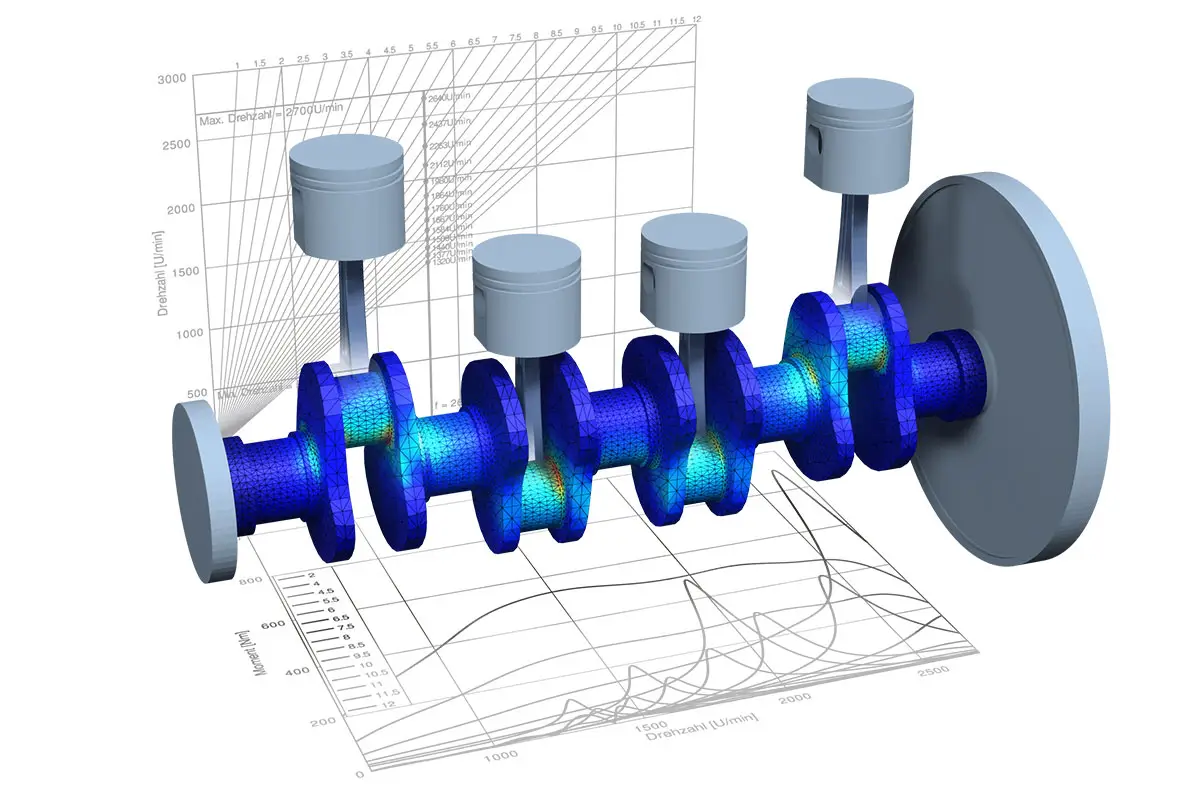

Product development & optimization through simulation

Using real operating states in form of measurements or load collectives as boundary conditions for product development enables a targeted design and optimization of components and assemblies.

From the concept phase to product validation: we support the individual steps of product development and optimization with engineering computations and interdisciplinary simulations.